Frequently Asked Questions

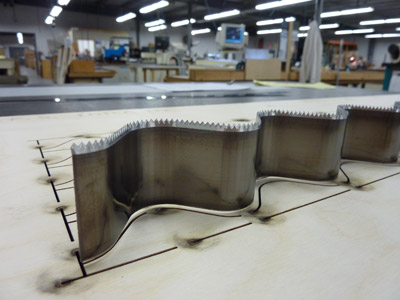

How do you cut the materials used in your dies?

Our Laser system, CNC router, as well as our water jet, can cut a variety of materials including rubber, plastic, metals, and composite materials.

What kind of materials do you work with in manufacturing dies?

Maple, birch, solid core composite, mild steel, aluminum, stainless steel, polycarbonate are all materials used as die bases and related tooling. We also offer Poly pads, Rubber, cellular PVC, Bar-plate, and Blue spring steel in a variety of sizes and thicknesses. The steel rule is pre-made in many heights and thicknesses and other important characteristics.

What is the lead time for Key Dies to make my die?

Key Dies is a two shift operation offering fast turn around times. Most dies would be ready to ship to you within two to three full working days from the receipt of your purchase order. Quicker production schedules on simple dies can most often be accommodated. Please call or email if you have a specific deadline. Key Dies will work with you to get your die to you when you need it.

Do I need to resend a file or die layout if Key Dies made my die before?

If there are no changes to the die you do not need to resend the information. Key Dies CAD department keeps all the files from dies we have made previously. Simply call or email us with either your or job number or ours, or your Purchase Order number previously used and we can make a new die for you.

I want to buy a die that has 300 inches of rule. Will my press have enough pressure to cut my parts?

A very general rule is that for each inch of rule in a die a press will need 400 to 500 pounds of pressure to cut. A die with 300 inches of rule would need a press with approximately 60 to 75 tons of pressure.

What types of files does Key Dies accept?

Key Dies gladly accepts files via email. In order to eliminate difficulties transmitting files, we have put together the following information. If we have not addressed a specific concern or you have need of further assistance, please call and request to speak to the CAD department.

- Our CAD system uses die-makers software called Cimex. The file formats with which we have the most success are as follows: DXF, DWG, DDES, EPS, Adobe Illustrator CS6, and PDF's created with Adobe Illustrator software using vector lines that are not rasterized.

- Formats we are unable to use include JPEG & TIFF files. We can see them, but can't convert them for use in our CAD system.

- Quark users note the following! We have no software to translate Quark files. Use Freehand or Adobe Illustrator software to convert QUARK files to EPS or AI Format.

- Tip for AutoCAD and similar systems with 3D capability. Save the required information to LAYER-0. We have no success with multiple layers. We can read up to AutoCAD 2010 files.

- Printers, please send us only the die line file. Crop marks and sheet edges are useful. DO NOT send graphics, text and color bars as these create problems for our conversion software.

- Short file names may be easily duplicated by others, which could lead to an accidental overwrite. (Ex: DIE.xxx, is not a good file name.) We recommend a name consisting of 2 or 3 letters from your company name and possibly your work order number. (Ex: ABC12345.xxx.) The suffix is very important. Please include it every time with every file.

- In order to expedite your work or quote; please add the following to the body of your E-mail: your name or contact person, your company name, your company phone number and any other pertinent instructions.

- Please make sure your file is attached before you send it.

How do I know my quote request or order has been received by Key Dies?

We do not acknowledge receipt of quote requests but attempt to do all quotes either same day or within 24 hours. If you have not received a price back within this time, please call or email and we will pursue the matter thoroughly. If you have a timeframe you need a quote within please indicate that on your initial request.

Every job order that we receive is acknowledged immediately via email, fax or your website. If there are questions on the job order or job-specific details that need to be addressed, Key Dies will acknowledge receipt of your order and follow up with a delivery confirmation when the job is entered into production. Whenever a job order proceeds to production, Key Dies will send email confirmation of shipping and arrival dates.

What is your shop tolerance?

Our standard shop tolerance on all machines under most conditions is + or - .015 inches. Some things that can effectually lower that tolerance are material thickness and die complexity. It should be noted, that under most conditions, we can adhere to a tighter shop tolerance of + or - .005 inches. It should also be noted that this tolerance applies to our dies and NOT to finished parts you get from the use of our dies. Material properties during the converting process can vary greatly and should be figured into the geometry of your tooling request.

Questions?

We’re here to help your important project become a successful reality. The first step is communicating one-on-one. How can we work with you?